TECHNOLOGY

Always on the forefront of technology, Doster’s VDC department offers a wide range of services to enhance your project.

From preliminary designs to 3-D building modeling, prefabrication to virtual reality, technology is paving the way for more streamlined project implementation, with safer, higher quality results.

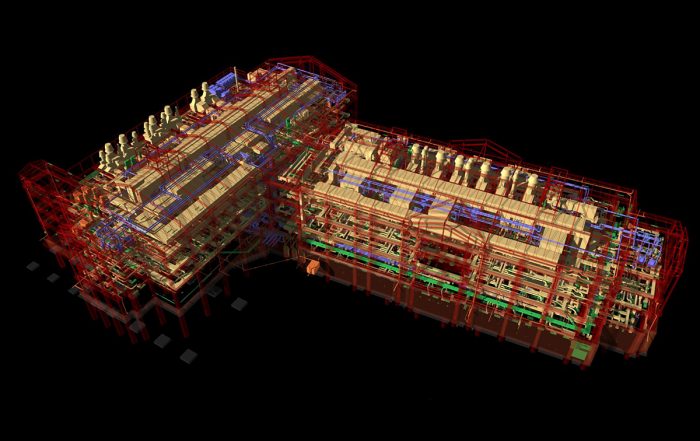

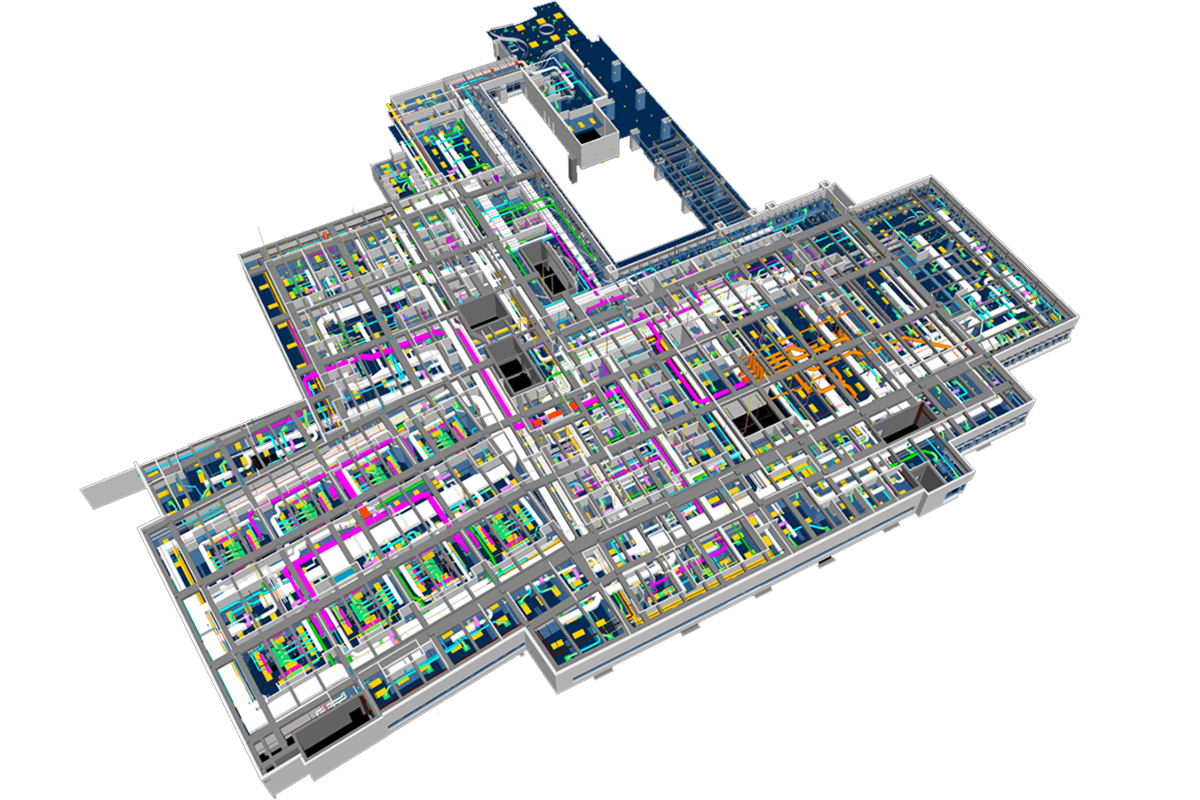

Building Information Modeling

Our VDC approach is anchored by Building Information Modeling (BIM). BIM provides a detailed, dynamic 3D model that integrates all aspects of the project—architectural, structural, and MEPF (mechanical, electrical, plumbing, and fire protection) systems. This unified model facilitates enhanced coordination, clash detection, and lifecycle management.

We tailor our implementation of VDC tools to meet the unique needs of each project. By assessing project requirements, scale, complexity, and client objectives, we determine the most effective combination and application of these technologies. This flexible approach ensures that we apply the right tools to enhance efficiency, accuracy, and overall project success, while delivering tailored solutions that align with the specific demands and goals of each project.

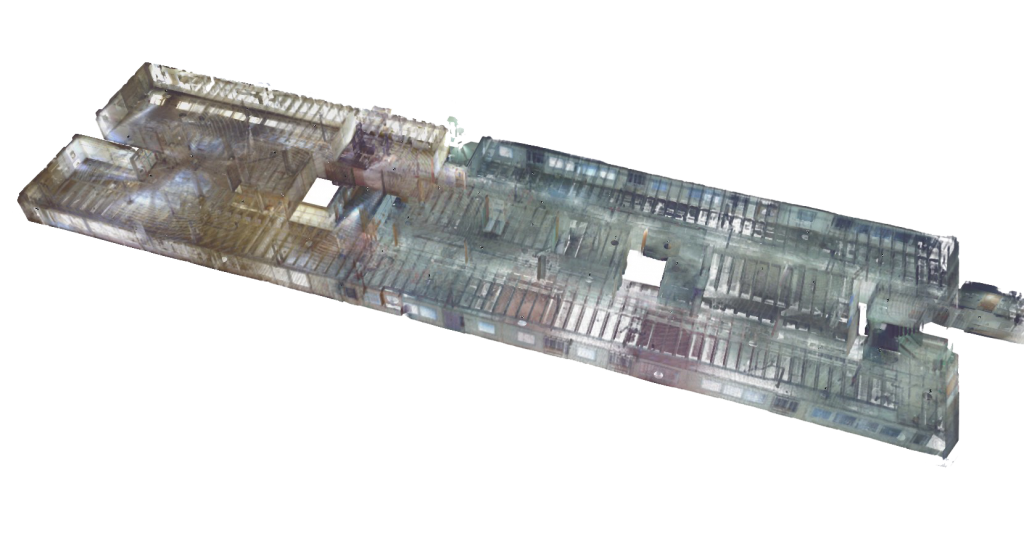

Laser Scanning

Our VD+C team owns and operates a 3D Laser Scanner for existing projects. Our team, in a matter of hours, can measure and document entire facilities to ensure all renovation and refit work truly matches the existing conditions. An accurate record of the existing building enables us to better plan construction activities, prefabricate work, communicate with design teams, and provide accurate as-builts to our Owners.

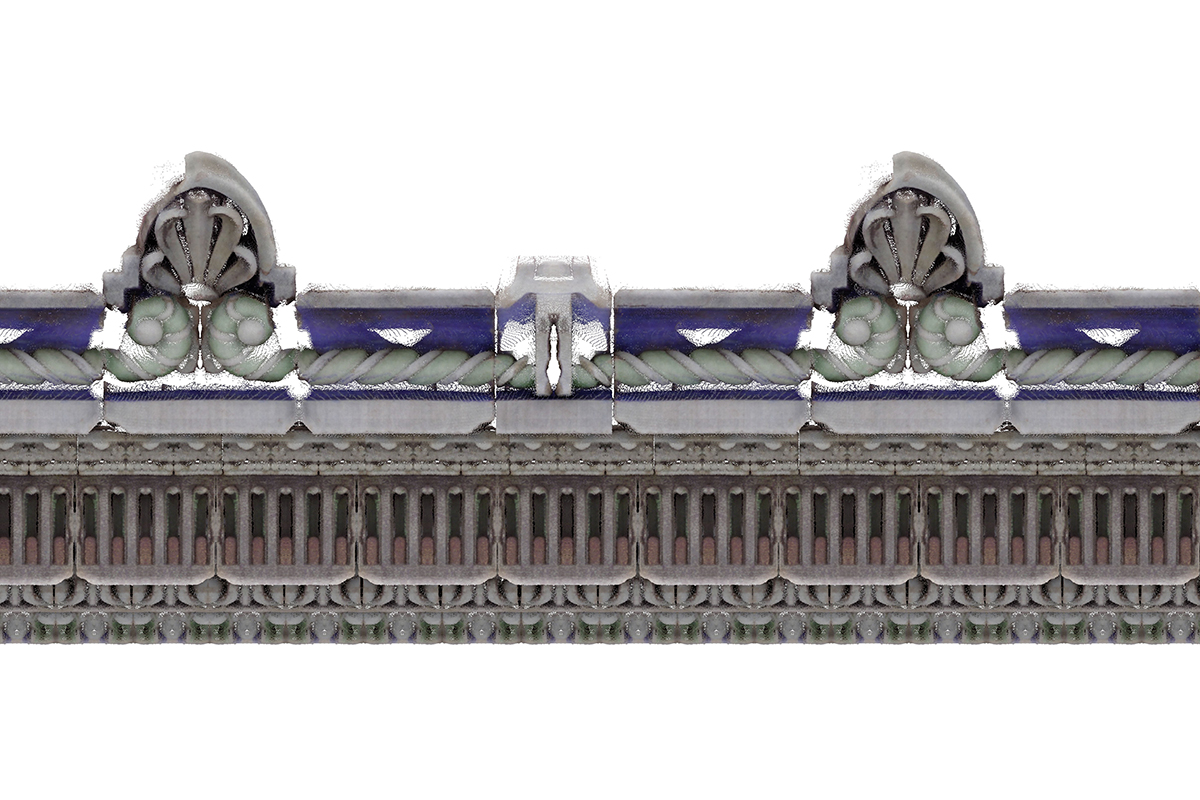

Laser Scanning at the Van Antwerp Building

The Van Antwerp Building, known as the southeast’s first skyscraper, was originally built in 1907. After time, concerns grew over the safety and stability of the building’s cornice. The cornice was ultimately demolished and the pieces were used as a fill for a road bed on the Van Antwerp family farm. In 2013, a complete historic renovation began under Doster’s management. Part of the renovation included a reproduction of the original cornice. As no drawings or photographs of the original cornice were available, we sent our VD+C team to the Van Antwerp family farm to unearth pieces of the original cornice. The pieces were cleaned, arranged, and scanned with 3D Laser Scanning Technology. Doster’s team then assembled the scanned pieces like a puzzle to create a digital, 3D, point cloud reproduction of the original cornice. These 3D representations were used to help create the new reproduction.

latest technology news

Read the latest news and updates from our VD+C department.

3 Ways Drones Are Improving Doster’s Construction Processes

By Charles Bradshaw, Virtual Construction & Technology Manager You’ve heard of drones and what they can do but do [...]

Maximizing Quality and Productivity with Trimble’s Robotic Total Station

In today’s construction climate, technology is no longer an anomaly; it’s a necessity. The benefits gained in the industry [...]

BETTER INFORMATION MANAGEMENT

Charles Bradshaw, Virtual Construction and Technology Manager at Doster Construction Company, has seen businesses of all sizes benefit from [...]